Machine Tool Spindles for Any Need

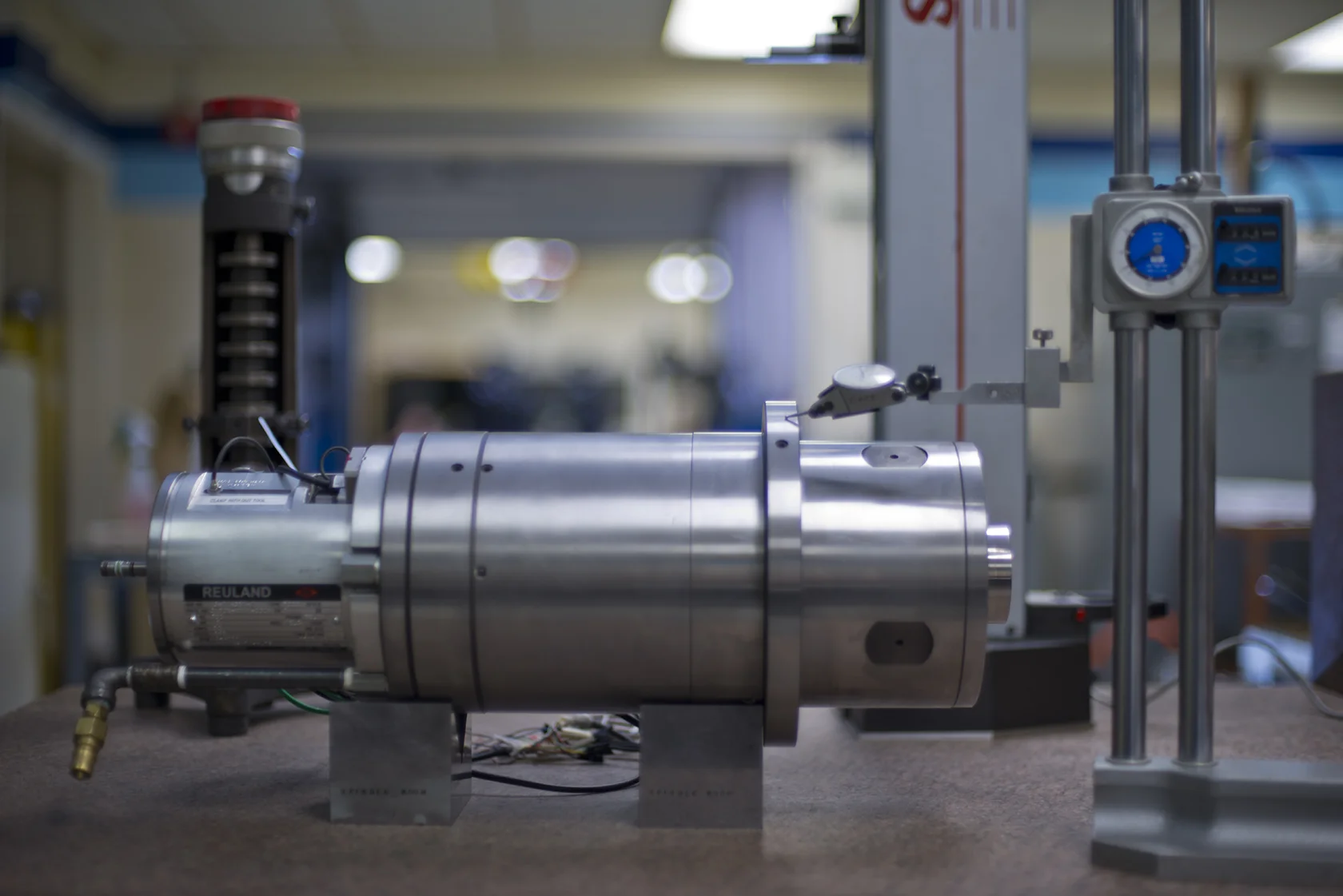

Colonial Tool manufactures, repairs and rebuilds all types of Machine Tool Spindles: CNC Machine Spindles, Motorized Spindles, Multi Drill and Tap Head, Box and Cartridge spindles, Gear Driven Spindles, Belt Driven Spindles, Cluster Spindles, and any Specialty Spindles.

We are a custom-build house with engineering and complete manufacturing of all machine tool spindles, CNC spindles and more. We offer 24-hour service with fast and reliable turnaround to minimize downtime.

Our operations have been around since before computerized numerical control (CNC) machinery, providing us with a historical look at machine tool spindles from their birth. Automated machining allows companies like yours to perform drilling, deburring, milling, slotting and much more through the use of specialty machine and boring spindles.

Colonial Tool engineering experts have helped push molds and dies smaller to create more precise machined parts, plus build boring and gear spindles with the high rotational speed needed to drive more advanced cutting tools. With satisfied customers across the continent, we’ve become a leader in the development, supply and manufacturing of machine tool spindles for nearly every industrial setting. See for yourself why Colonial Tool is the industry leader when it comes to spindle machines!

Our capabilities as a machine spindle manufacturer allow us to build:

Spindle Manufacturing

Colonial Tool Group has stood at the forefront of machine spindle manufacturers for nearly a century, which gives us a long and proven history with creating quality products for clients of all kinds.

With expertise and state-of-the-art technology, our robust staff of spindle machine engineers, assemblers and other professionals will do what they can find the best solutions for your needs. It all begins with a consultation, where we'll discuss your desired applications and speak about your requirements in detail. From carpentry to military purposes, we're confident we can assist you.

Spindle machines are far from one-size-fits-all devices, as you can separate them into a few broad categories — like belt-driven, air-driven and electric — and specialize their components to meet the necessary workload.

We can manufacture spindles to suit a wide range of different machines, including lathes, millers, drillers and grinders. Understanding the output you need from your machines will go a long way in determining the specifications, including operating speed, input voltage, power, maximum torque, size and angle flexibility.

Other customizable components of your spindle include the seals, as well as the bearings, which come in three types:

Angular contact bearings

Double row taper bore roller bearings

Taper roller bearings

We accommodate a vast array of mounting interfaces as well for optimum fits. You can select from a few of the following examples, including:

Threaded, standard and flanged bores

Shafts and arbors

Collets and wheel collets

Internal and external tapers

Machine spindles can be created to include automatic-balancing or air-purging options. We can also implement high-frequency drives, which use liquid-cooling to regulate heat functionally, or you can select spindles that use coolant feeds.

You can also maintain a running log of information to keep efficiency high. Spindles can be equipped with encoders and resolvers to provide details about position and speed.

After we sort out the information and lay out the groundwork for a plan, we can move on to machining and manufacturing the different parts as needed.

Who We Serve

Some of our spindle customers are Ford, GM, Chrysler, CAT, Cummins, MAG, Comau, Ingersoll Production Equipment, Linamar, Red Viking, Raven Engineering, Cell Con, large and small machine houses and die shops. These manufacturers require incredibly precise spindle tooling, and have trusted Colonial Tool to provide it to them for many years.

We engineer each and every machine tool spindle to achieve the maximum possible rigidity, while meeting or exceeding the speed capability required for the application. Wherever you see a CNC spindle or specialty spindle carrying an RAS tag, rest assured that you get the absolute best performance in quality and reliability.

Everything You Need to Know About Spindles

A spindle machines primary function is to hold and rotate cutting tools for various machining applications. We develop motorized spindles to meet a wide range of spindle tooling needs and meet different performance standards. Typically, spindles, both standard and specialty spindles, can be grouped into three broad categories that can guide purchasing decisions for businesses like yours:

Belt-driven spindles represent cost-effective spindle tooling solutions that will work with specialty equipment and applications. Belt-driven spindles typically provide a lower cost option.

Air-driven spindles provide some of the longest spindle lives and are easy to cool through both air and oil-mist options, which works for most industrial settings.

Electric spindles represent the latest innovations, bringing the highest speeds, angle flexibility, power output and optimal use of torque.

Custom and standard spindle tooling applications such as cluster spindles that rely on belt-driven motors are also available.

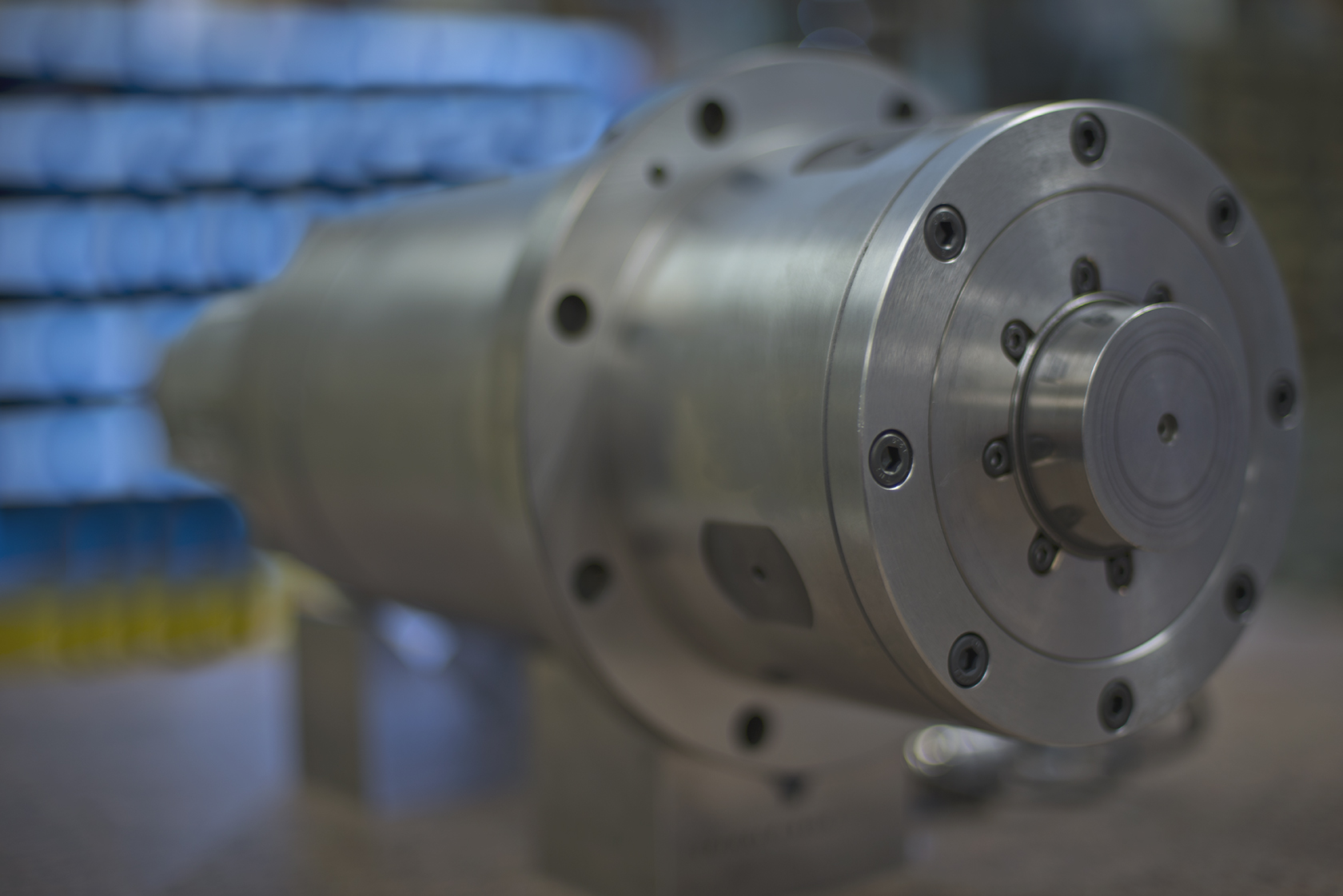

You’ll often hear about cartridge spindles that use a cylindrical design for the best mounting as a boring spindle. Cartridges allow for easy transition and changing of machine spindles to minimize the downtime required to shift operations. Typically, they can work with almost any motorized spindles.

Block spindles are flat-mounted units with bearings in the block itself, giving you a higher rigidity though a slower shifting of tools. Block gear spindles need to have the entire unit removed to switch spindles, and will need a tram when installed.

Common Spindle Applications

The thousands and thousands of machine tool spindles we’ve built over the years have ended up in almost every feasible application scenario. Understanding the common usage may also help you select the proper machine spindle for your operations, such as the needs or benefits for gear-driven spindles, belt-driven spindles and cluster spindles.

You can also contact Colonial directly to get fast answers to your questions, or a smart quote on your custom spindle development.

Different motorized spindles will perform well in different scenarios. These preferences can include:

Boring spindles: Operate efficiently in machines using integral engines for increased punch

Drilling spindles: Strong thrusting capacity and better radial load ratings

Grinding spindles: Provide grinding wheels with precision finishing, as well as size and surface finishing touches

Hobbing spindles: Specific spindles that cut gear tooth profiles

Milling spindles: Can support a wide range of cutting features into moldings and millwork, with some options for other machining tool operations

Tapping spindles: Create internal threading when used with taps

Tuning spindles: Facilitate the proper use of turning centers, as well as vertical and horizontal lathes

The Colonial Tool Story

Since 1921, Colonial Tool has produced hundreds of thousands of spindles. We’ve become a go-to machine spindle manufacturer for companies in Windsor, Guelph, Stratford, Detroit, and throughout Ontario and Michigan. We are also the leading spindle manufacturer for various industries including aerospace, military, and automotive

Manufacturing excellence, combined with total capability, including metallurgical expertise with in-house heat treatment, enables application-specific materials use and treatments. Ultra-precise tolerances are routinely held, using state-of-the-art inspection equipment.

Over 85 years as a leading machine spindle manufacturer, RAS has stayed at the forefront of spindle technology. Engineered solutions optimized for all performance elements, coupled with customized proprietary designs, ensure world-class results.

With over 330,000 motorized spindles built, two manufacturing plants and customers in four continents, Colonial is capable and ready to handle any spindle project small or large.

Start Your Work With Us

Browse through our spindle pages. You’re almost certain to find something that will fit your application.

If you have any doubts or questions, don’t hesitate to contact us. Our sales department will gladly answer your questions. You can also call us toll-free at (866)-611-5119 to learn more about pricing options, machine spindle manufacturing capabilities and support or repairs for your OEM equipment.