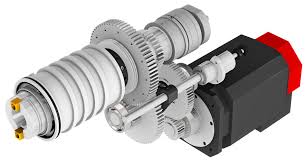

>Gear Driven Spindle Repair & Rebuild Services

Colonial Tool Manufacture, repairs, and rebuilds all types of Gear Driven Machine Spindles

These are very rugged spindles, well suited for heavy metal removal applications. Large arbor mills requiring a lot of horse power and torque are prime examples of gear driven spindles. For heavy boring and/or multiple boring cluster, gear driven spindles can be used. Double enveloping or parallel helical gear reducing systems are available, for extreme, heavy duty applications. Where application dictates, coolant can be brought to the tool through the spindle shafts. Usually main spindle bearings are permanently grease lubed, while gear train is oil lubricated through a closed, looped system that is integral to the spindle, inclusive of oil reservoir. This facilitates a relatively compact package that requires little maintenance and/or additional components supplied by the end user.

If you have a heavy metal removal application and are considering using a gear driven spindle, please call us. We have unrivaled experience in this field