High-Level CNC Broaching Machine Manufacturer

Colonial Tool may not be the only company capable of manufacturing CNC broaching machines, but few can offer the same experience in high-level broaching machines that offer advanced capabilities, practical features and legendary reliability. We design our CNC broaching machines to:

Maximize productivity: All of our cnc broaching machines include indexable heads and quick-change broaches and cutters so you can work faster.

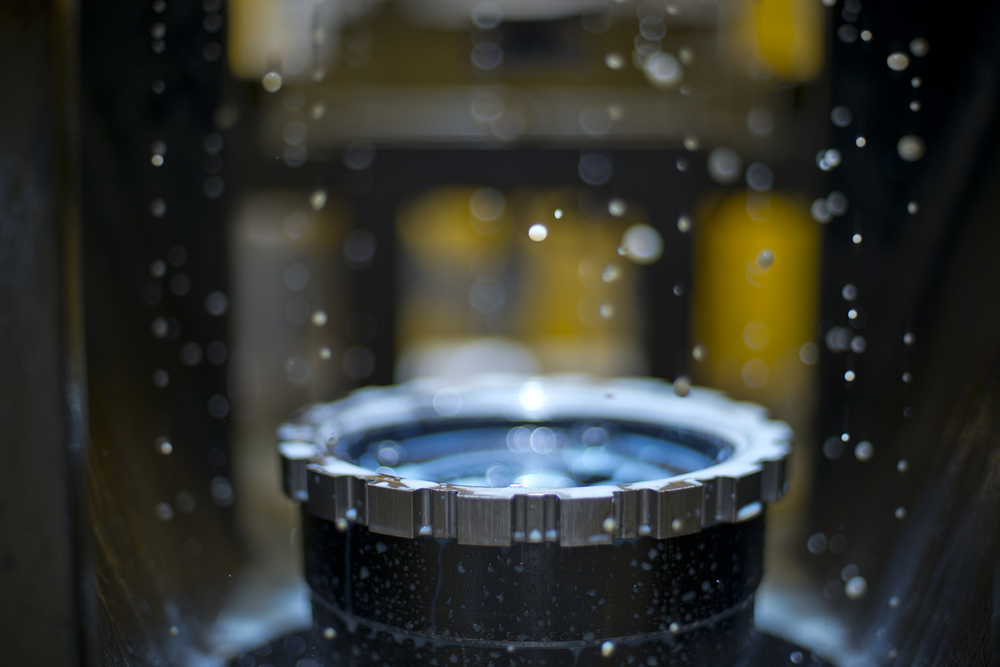

Minimize downtime: We use quality materials and components in our CNC broaching machines for greater reliability and less downtime.

Ensure quality: We use advanced engineering and manufacturing to ensure the highest tolerances on your CNC machine speeds and position for the best results.

The result is more working time and less scrap from your CNC broaching machine, which directly adds to your bottom line. Our precision-built and sharpened broach machine tooling allows you to work longer without the need to adjust or change to a different tool, further optimizing your working time. With advantages like this, it’s easy to see why more and more customers are turning to Colonial Tool for their high-level CNC broaching machines.

Broaching Machines - Designed, Built, & Delivered!

Your business has its own specific broaching and machining needs. That is why here at Colonial Tool we offer a broad range of different broaching machines. Instead of selecting a standard model that isn't designed for the type of machining you do, opt for the Colonial Tool broaching machine and tooling that lets you work more efficiently. Choose from the following models:

Vertical Pull Down

Vertical Service

Twin Cylinder

Table Top

Dual Ram Surface

Push Up Pot

Tri-Way

Horizontal

Vertical Turbine

Horizontal Turbine

Specialty

Do you already have experience with these different types of broaching machines and know which one suits your business? If so, you can simply let us know which model you’re interested in, and we’ll give you more information and a free quote.

If you’re not sure which CNC broaching machine you need, we invite you to contact us to discuss your broaching machine requirements. We have decades of experience as a leading broaching machine manufacturer and repair company and can help you choose the right model. Tell us about the cutting and machining operations you would like to perform, and we’ll suggest the broaching machine and tooling that is best adapted to your requirements.

CNC Broaching Machines

Modern production manufacturing dictates usage of the latest available technological advancements. While CNC broaching machines have been around for a long time and are considered matured products in terms of production types, continuous improvement of automation and controls have been a major focus here at Colonial. Our engineering groups are keeping abreast with all technological breakthroughs and are leading the charge in offering tomorrow's technology for today's customers. CNC equipment and broaching machines are perfect matches, due to the type of productions (medium or long runs), that traditionally are associated with broaching.

Other suppliers make you choose from ‘standard’ catalog CNC broaching machines that may not have the features and capabilities you’re looking for. As a manufacturer of our own machines, our team here at Colonial Tool has the advantage of custom-building a CNC broaching machine that perfectly meets your needs. An optimized machine allows you to:

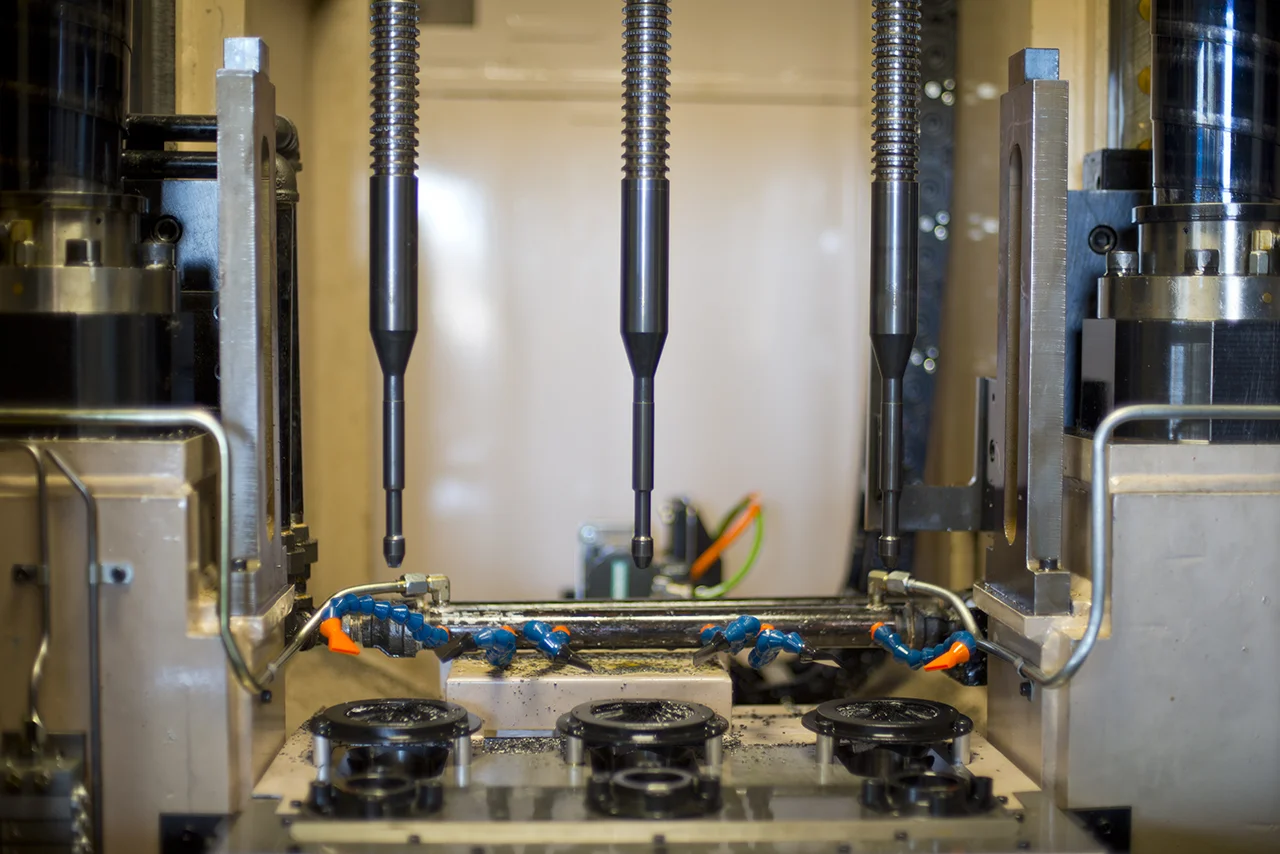

• Include indexable tooling for fast cutting tool changeover.

• Increase your speed and productivity.

• Decrease your downtime and set-up time.

• Improve the quality of your parts and reduce scrap.

Our goal is delivering top notch, trouble free CNC broaching machines to ensure that you are satisfied as a customer while we maintain our good reputation of reliable broaching machine builders.

Broaching Machines

Colonial Tool Group carries on a tradition of respected machine & tool design and build capability, that began in the late 1920s. Today our know-how and experience has broadened substantially, but our core business still remains in the precision manufacture of machine tools.

We have developed a complete line of broaching machines, that include single and dual slide pull-down, and table-up, as well as standard surface broaching.

Let Colonial Tool estimate the requirements for your broaching machine. Send us your part prints and allow our engineers to assist in your part processing for the most logical method of operation to maximize up time and reduce head-aches. We can design your broaching tool to a dedicated operation, or accommodate a general field of similar parts. Quick-change broaching set ups reduce your changeover down time. In-field service engineers are available for quick response on any manufacturing machines.

Electric Drive Broaching Machines

Thanks to our years of experience designing and manufacturing high-quality electric drive broaching machines, we can offer some impressive specifications and capabilities:

Up to 72" stroke

Pulling capacity up to 30,000 lbs/ 15 tons

Machine sizes range from 48x60" up to 96x146"

Coolant Res. Capacity 200- 250 (gal)

Max cutting speed 30 FPM

Max return speed 50 FPM

No pits or platform needed

Approximately 50% less floor space needed because of no hydraulic unit

No hydraulic oil to buy or dispose of

Lower electric cost because of run on demand

Less heat

Less noise

Better part finish and tool life due to smooth cutting action

Cell friendly (self contained).

Fast change over for internal spline or keyways

Single station standard 2 or 3 station optional

We invite you to give us a call and tell us what you're looking for in your next electric drive broaching machine. Our high-level machines are sure to impress with their performance, reliability and advanced features. Once you've explained your requirements and expectations, we'll prepare a quote for the broaching machine that will suit your business and machining needs perfectly. Come and find out how Colonial Tool has become an industry leader in high-level broaching machines manufacturing and service.

The Machines That Make the Intricate Parts

Colonial Tool Group's CNC broaching machines are used globally and our customer service is second to none. Our reliability is what has kept us in business for 80 years and if fast and efficient machine parts are what you're looking for contact Colonial Tool Group today.

Aircraft turbine disc broaching machines

Our broaching machines are based on the original but updated Lapointe broach machine designs. Colonial is the owner of all Lapointe broach machine engineering for machines manufactured in North America prior to 1986. Service and replacement parts of these older Lapointe machines and index tables are available from Colonial.

Simple, internal, table-up broaching machines, up to 300" stroke 6 axis multi-level horizontal turbine disc broaching machines and index tables are the wide range of Colonial’s abilities. Machines can be designed application specific or choose a standard design with a quick delivery

240-in-stroke Horizontal Broach Machine with 5 CNC axis

-buyer Pratt & Whitney

A turn key design and build tuned to deliver maximum precision at 17 tone force

Pratt & Whitney run production with this state of the art machine sold in March 2009, the news spread around the word starting with aerospace-technology.com as Colonial Tool supplied cutting edge technology to the aerospace industry.

Custom Builds & Specialty Designs

When companies make the parts that matter for automotive, aerospace, medical, die/mold and other industries worldwide they make them with Colonial. A leader in advanced manufacturing machine tool technology, Colonial enables its customers to realize the highest level of quality, with the fastest time to market.

If there is a specific job you need customized machinery for Colonial can help. We have the capability to supply custom built equipment, based upon your design requirements. We design our machines specifically for each customer to optimize their need and potential taking into consideration many different factors that facilities retain.